More info

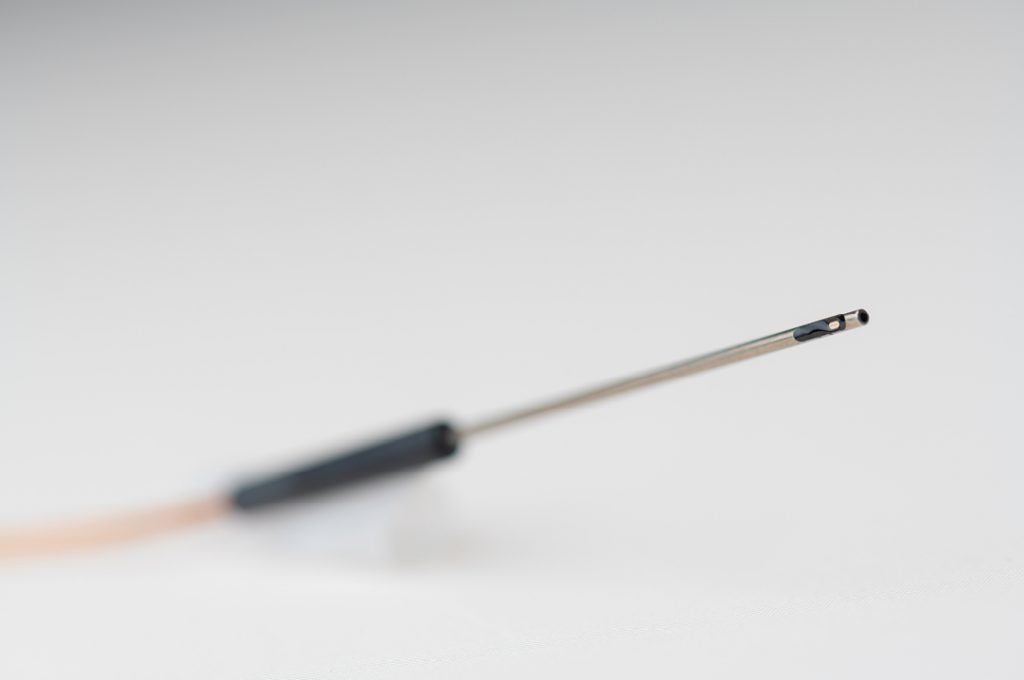

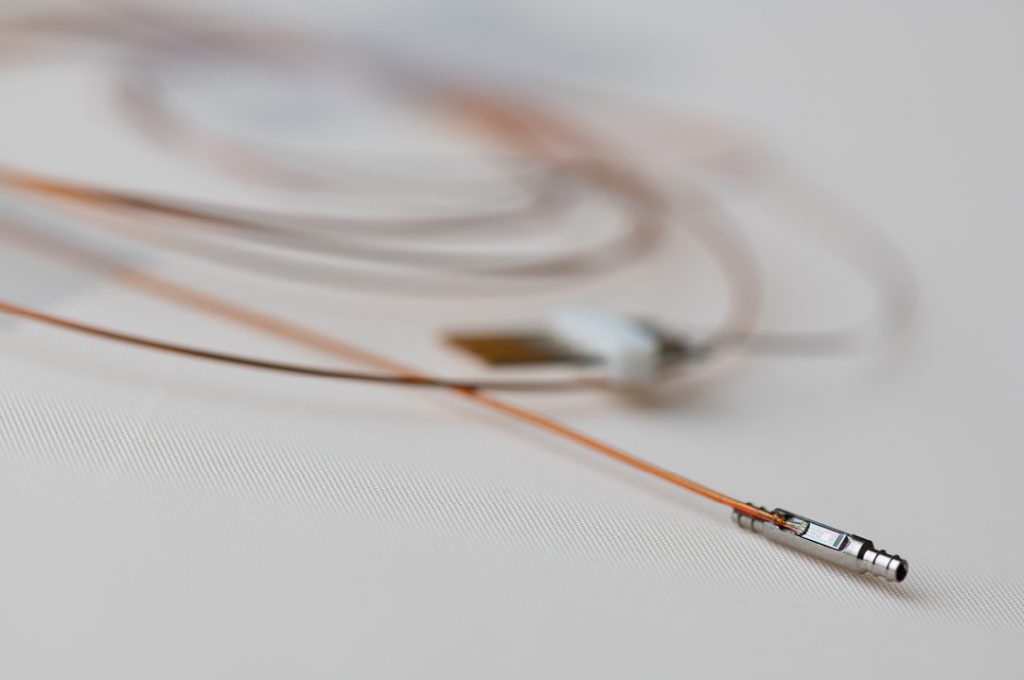

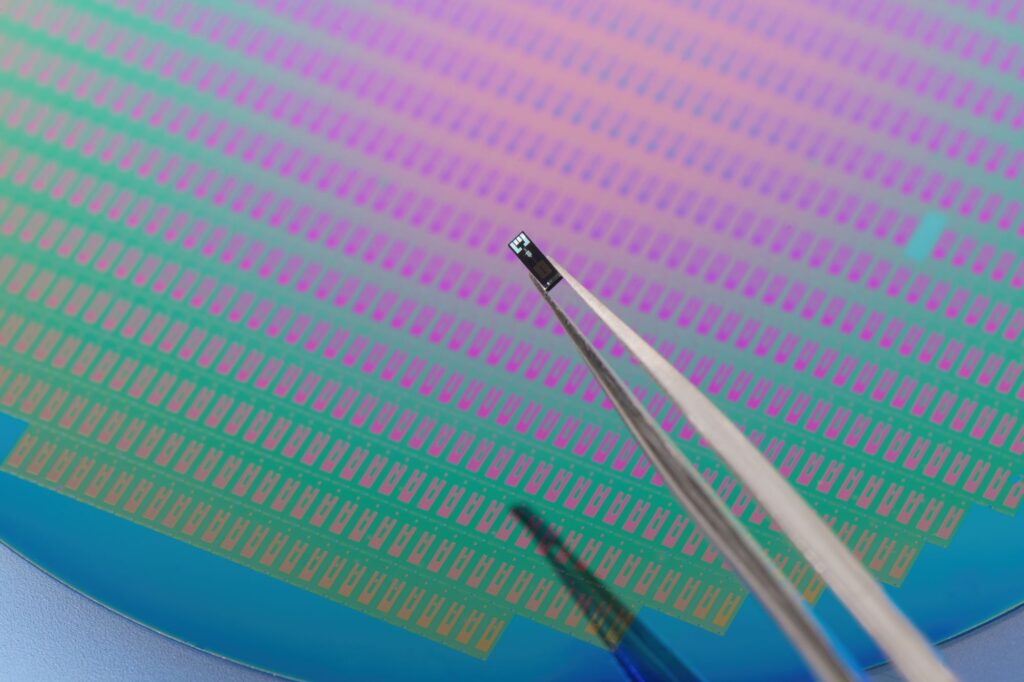

At Sentron, we develop and produce sensors in our inhouse semiconductor production facility. Through many years of experience and specific know-how for die attaching, wire bonding, encapsulating, steering and compensating sensors, we also design and manufacture sensor assemblies and complete products with our pH and pressure sensors as well as with third party sensors.